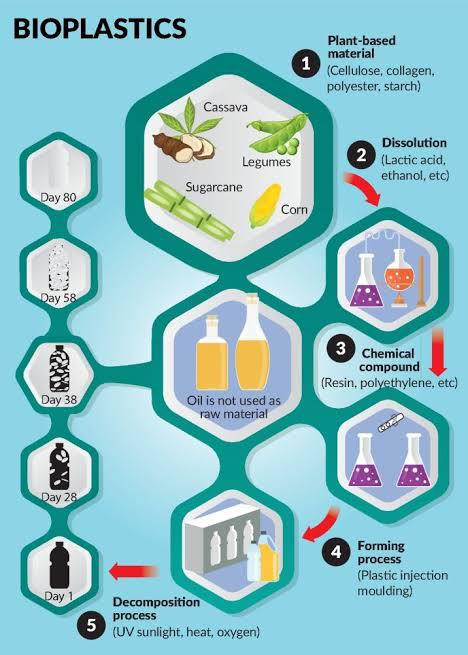

Process

Application

Avios APIO/23 is an end compound suitable for film blowing applications and is specially developed for carrier bag. APIO 23 is a good and sustainable alternative for PE bags and is a competitive alternative for currently used biodegradable plastic bags.

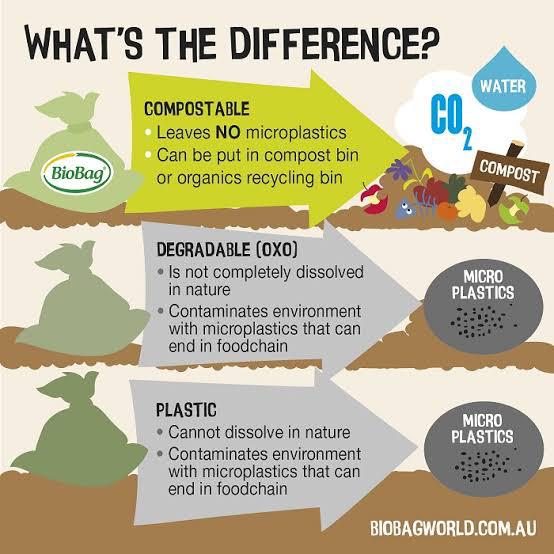

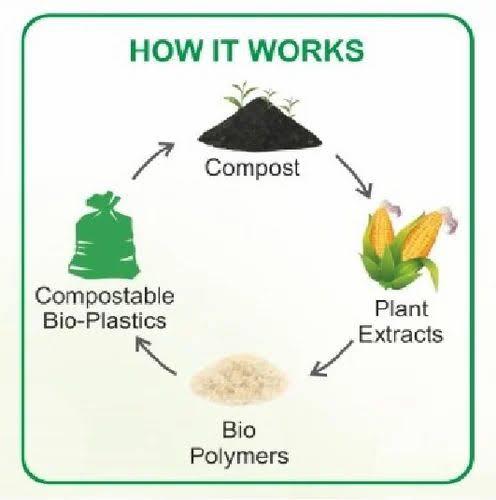

Avios green APIO/23 is a Biodegradable and Compostable compound that contain starch.

The brand ensures the absence of heavy metals and harmful substance in all Avios formulations. An excellent disintegration of the manufactured products and the ecotoxicity of the humus are assured and certified. The biodegradability of at least 90 % guaranteed within 6 months for industries and 12 months for home.

Packaging and Storage

Avios APIO/23 are supplied in the form of granules inside a carton box. Temperatures during transportation and storage may not exceed 50 °C at any time. Change in moisture content (either loss or gain should be depending on atmospheric conditions) should be avoided during longer term storage. Well packaged product should be stored under 23 °C and used within 3 months with LDPE liner bag or within 10 months with Aluminium liner bag. Avios APIO/23 should be stored in closed packaging in a cool, dry place out of direct sunlight. During production, once the bag has been open, exposure to the weather condition must be avoided for more than 5-6 hours. The unused material is recommended to seal it hermetically and to dry it 4 h to 80 °C before subsequent reuse.

Quality control

Avios APIO/23 is produced as a standard material in a continuous production process. The melt flow index, MFI at 190 °C, 2.16 kg, according to ISO1133 has been defined as specified parameter for quality control. A certified can be provided with each lot number upon request. The Avios APIO/23 granules have to be pre- dried (4 hours at 80°C) before MFI measurement in order to obtain accurate values. Other data given in our literature are typical values, which are not part of our product specification for Avios APIO/23.

Processing

Avios APIO/23 is an innovative type of bioplastic design primarily for film blowing. Avios APIO/23 is processable on all conventional extrusion film blowing or casting lines with standard screw setting. Preferred screw design is a PE type. The information reported should be considered for general guideline in Avios APIO/23 processing. Fine tuning the film blowing process may be needed to obtain the optimum process parameters.

| Processing Temperature profile |

Values |

| Feed zone temperature |

150-165 °C |

| Melt zone temperature |

160-170 °C |

| Die temperature |

155-165 °C |

| Maximum temperature |

175 °C |

| Melt temperature |

145-155°C |

Operating Advice

Overheating of products should be avoided (due to degradation of polymer). Before production, make sure that all temperature zone work correctly. Do not allow material to remain hot inside the extruder for extended periods as the material can degrade. Therefore, do not heat products over 160 °C for long times and do not over 150 °C when machine is not running. In case the machine used to run with other materials, high melting synthetic polymers (HDPE, PET, PVC, PA), it is recommended to use a correct transition thermoplastic polymer ( LDPE with MFI 4-8 g/10 min) and then reduce the temperature gradually to the required setting. The extruder can be usually purged for 10-20 minutes with low melting thermoplastic polymers using the above setting temperature setting. Avios APIO/23 is not compatible with masterbatches or synthetic or olefin additives they can cause welding problems.